Simplifying Blueprinting with SUN Collision Repair Information

By |

Editor’s Note: In tandem with the recent launch of the SUN Collision Repair Package, this article takes a deeper dive into the blueprinting process for auto body collision repair. Blueprinting is typically a tedious process, with technicians identifying the damage and estimators painstakingly putting together blueprints, searching for OEM repair procedures, parts, and labor requirements, then manually entering it all into their estimating system. Now, with the Repair Package, estimators/service writers can whip up blueprints in seconds. This powerful feature seamlessly integrates with the estimating system, to easily centralize OEM repair information and estimating data in support of insurance claims.

What is Blueprinting?

Most of us are familiar with the term, blueprints, and the fact that they’re used in building and home construction. But blueprinting is an essential guide that can be used for nearly anything, including streamlining your auto body repair shop. A blueprint is specific to the industry and project, whether it ensures a building meets code or a project is completed safely and accurately. The collision repair blueprinting process creates a comprehensive overview of the entire repair to fast-track the process.

When used to its fullest, a blueprint for collision repair saves time and labor and helps ensure accurate estimates for insurance companies and other stakeholders. Blueprinting also helps ensure more accurate and safe repairs, thus, increasing customer satisfaction and your bottom line.

The Collision Repair Blueprinting Process

Most collision repairs begin the same. A technician documents the VIN, mileage and other basic information, and also may scan the vehicle for electrical system issues. The typical initial data is all you need to access the latest OEM information from collision repair software and it’s the foundation for the repair blueprint.

The next step is typically an appraisal of the damage. A technician visually inspects the vehicle, checking the alignment of doors, the trunk and panel gaps. The process continues on the interior, and finally, the undercarriage is examined for issues. The results of the inspection identify damaged areas and what parts will be removed. Modern vehicles are also tested to identify any Advanced Driver Assistance Systems (ADAS) and other system issues.

Once a collision repair center has all the data to determine the proper repairs, needed parts, and other aspects, a blueprint is created. The ideal blueprint will be a well-planned roadmap for the most efficient and accurate repair process.

Collision repair shops remain ahead of the curve by heavily relying on collision repair technology and blueprinting. These body shops can provide more accurate estimates that can help prevent delays related to undiscovered damage. The beauty of an accurate blueprint is how it prepares collision repair technicians, insurance companies and customers with a complete picture.

Building a comprehensive blueprint takes time, but it ensures more accurate repairs, fewer headaches and improved efficiency. And you’ll avoid those surprises that can bring the whole repair process to a halt.

Optimizing Collision Repair Blueprinting with OEM Data

In the collision repair world, we all know that even a seemingly minor fender-bender can result in much more damage than meets the eye. No matter how much experience a repair technician can rely upon, there are simply too many components and interconnectivity beneath the surface. A comprehensive collision repair blueprint can ensure every repair process covers all the bases.

On-demand OEM collision repair information from SUN Collision is just as advanced as the vehicles technicians work on daily. A click of a button is all it takes to access nearly every detail of a repair process. The latest repair information for wiring, sensors, parts, and processes checks all the boxes for a complete and inclusive repair blueprint.

Advanced collision repair software helps technicians complete safe, accurate collision repairs based on thorough blueprints. Combining the latest repair technology and detailed blueprints reduces comebacks, ensures higher-quality repairs, and decreases cycle times. These tools also help create more knowledgeable and skilled collision repair technicians.

Collision Repair Software and Repair Blueprints

On a job site, a construction blueprint spells out every detail for the contractor, from what materials to use to how to use them. In your body shop, a collision repair blueprint does the same. Repair technicians can rely on a detailed blueprint that leaves little room for error or confusion. Every panel, part and fastener are identified, and every repair process is laid out in a step-by-step guide.

A body shop blueprint isn’t an estimate in the traditional sense it’s a proven strategy for restoring a vehicle to pre-collision condition. So how can body shops streamline vehicle collision blueprints and include all the processes, materials and parts? SUN Collision helps body shops quickly find all the OEM information they need to make the process more manageable.

What blueprint information can you access with collision repair software?

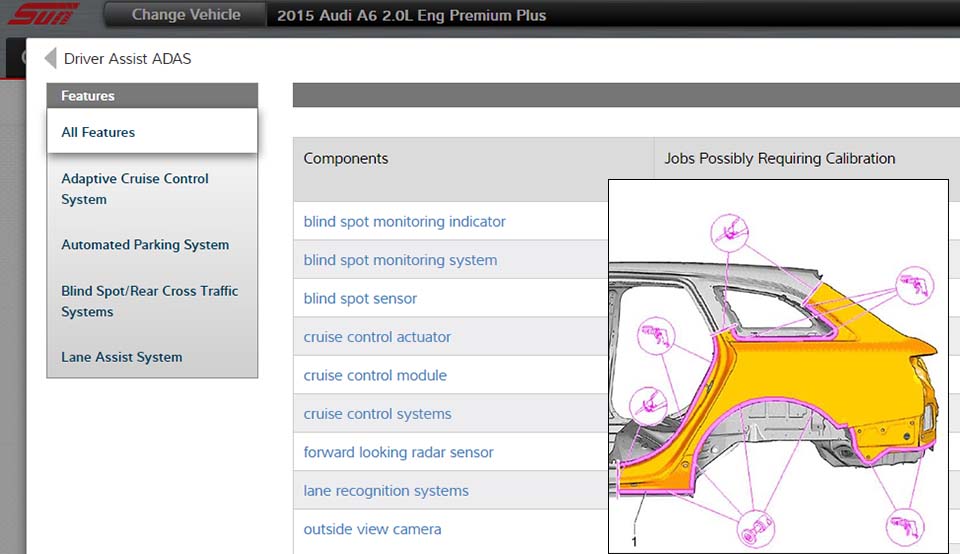

ADAS

If you operate a body shop, you know how complex vehicle technology can be, especially ADAS. To keep up with this and other vehicle advancements, you can put your own advanced technology to work with the latest software. From the latest OEM information to on-demand wiring diagrams, creating a blueprint for repairing ADAS and other advanced systems is a breeze.

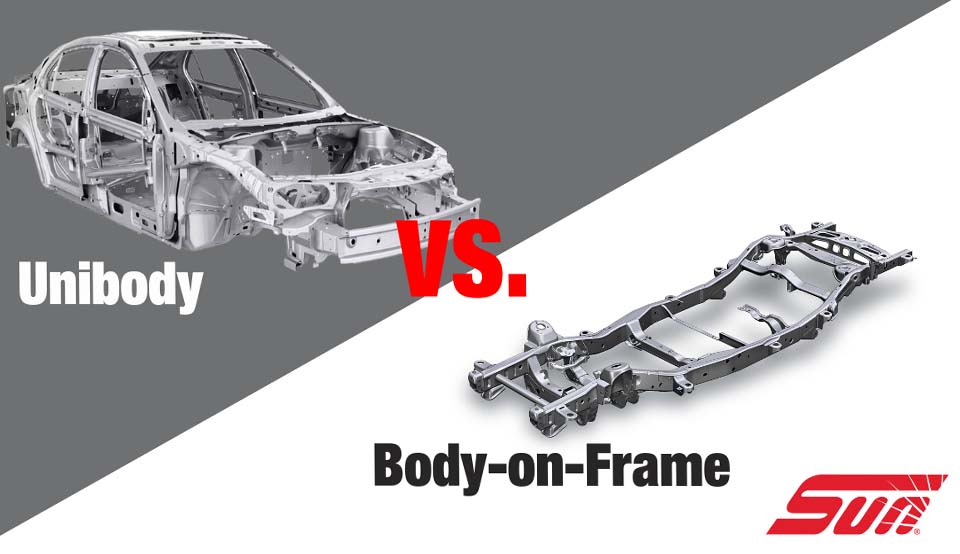

Body & Frame

A completed collision repair is only as safe as the body and frame that supports everything else. Creating a comprehensive blueprint will include details about everything from structural adhesives to sectioning processes. With on-demand repair software, your body shop can access data for materials, panel removal, structural repairs, and other crucial information.

Materials

It’s easy to look up OEM data for the latest vehicle materials using the basic information from the inspection. Composite panels, high-strength steel components and aluminum parts are just some materials technicians must understand when repairing modern cars and trucks. The software provides up-to-date and comprehensive material data, processes, and more.

Paint & Finish

The finishing touches on your latest collision repair are critical. Since the deal is for your body shop to restore a vehicle to its pre-collision state, the final paint and finish must be exceptional. A collision repair blueprint should include surface preparation, application processes, materials, and protection all you can easily find with the most recent paint and finish data.

Common Repair Procedures

Body shops can also rely on SUN’s extensive database of common repair procedures for nearly every collision repair. From more precise diagnostics to the finished repair, all a collision technician needs is some essential information to get the whole picture.

OEM collision repair data is essential before and during the repair process. SUN Collision presents information in a familiar and user-friendly format that speaks the repair technician language. Technicians can find the latest OEM repair information using familiar terms like VINs, YMM, and other vehicle- or component-specific details. It’s an intuitive platform built to meet the day-to-day needs of body shops by providing the most up-to-date OEM information. If a technician can use Google, they can use our advanced search engine, 1Search Plus, without missing a beat.

Elevating Blueprinting with the new Repair Package

SUN Collision’s new Repair Package makes blueprinting more precise and efficient. With just a click of a button, the powerful tool compiles a comprehensive repair package, including essential repair procedures, intricate illustrations, diagrams, and all the necessary OEM part numbers. The Repair Package maps with your shop’s estimating system and leverages industry-standard guidelines established by the Collision Industry Electronic Commerce Association (CIECA).

To create the repair package, SUN Collision software sources CIECA data for the estimate. When users click on an estimate line item, SUN Collision presents information for known part numbers and other details, and allows for manual searches to fill in any missing information. Users can further customize their reports, adding content such as wiring diagrams and component locations.

SUN Collision Repair Information Software

There is no substitute for experience and training in collision repair. Many technicians have years of experience, and that expertise is invaluable for many types of body repair. But as vehicle manufacturers continue to adopt new technology, keeping up with the latest specs and procedures can be challenging.

One of the best ways to stay in the loop with innovations and advancements in vehicle technology is collision repair software. More and more collision repair facilities are implementing technology like our SUN Collision Repair Information to supplement the experience and knowledge of technicians. Repair software can also make adding blueprints to the repair process much easier.

GET STARTED TODAY!

Get your free no-obligation demo or talk with a collision repair expert at 877-840-1973 to see how on-demand OEM information can take blueprinting and collision repair to another level

Chris Bonneau is the Business Manager for the SUN Collision product line. He has been in the automotive repair and collision industry since 2006. Chris has served in several roles at Snap-on, including Regional Sales Manager for the Southeast United States and Supervisor of the Mitchell 1 SocialCRM Marketing Services. Chris is also an alumni of San Diego State University.